English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Is There Anything We Need to Pay Attention to When Transporting Wires and Cables?

2025-01-12

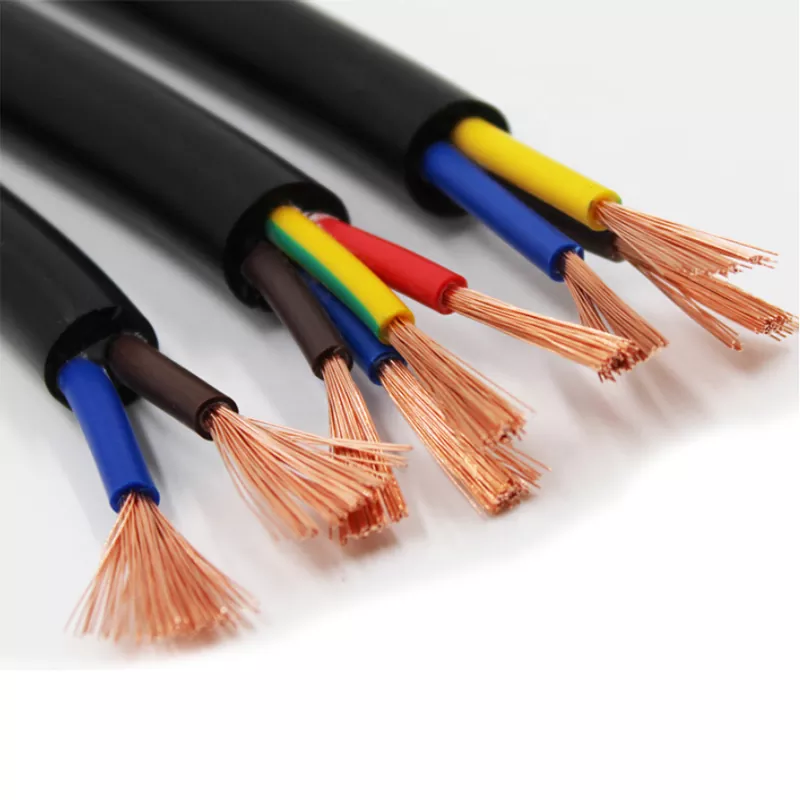

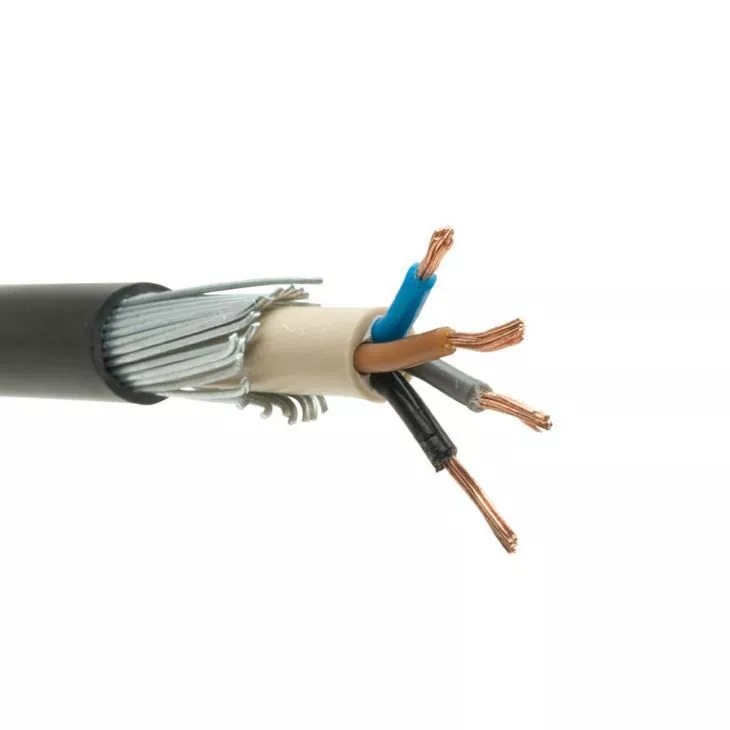

Wires and cables are highly popular in modern production and life. Any machine that requires electric drive cannot do without the support of wires and cables. The main components of wires and cables are metal wires, insulating sleeves and protective sleeves. This requires that the transportation and storage of wires and cables must be strict and cautious to avoid damage to wires and cables during transportation and storage.

1. Wires and cables should avoid falling from heights during transportation. It is forbidden to drop wires and cables from heights during loading and unloading. Especially under low temperature conditions, the insulating sleeves and protective sleeves of wires and cables are relatively brittle and hard. Falling from high altitudes will cause the insulating sleeves and protective sleeves to crack.

2. The insulating sleeves and protective sleeves of wires and cables are mostly rubber products and cannot withstand excessive sunlight. Try to avoid wires and cables being placed in open places, and cable reels are not allowed to be laid flat.

3. When packaging wires and cables, several cable reels should not be hoisted at the same time to avoid dangerous accidents. The placement of cable reels on transportation tools such as vehicles and ships must be reasonable and fixed to prevent the cable reels from turning over or colliding due to shaking during transportation, causing damage to the wires and cables.

4. Wires and cables generally have low corrosion resistance. It is strictly forbidden to contact with acids, alkalis, and mineral oils. If they have to be placed close to corrosive substances during transportation, necessary isolation is required. The existence of substances that damage the insulation protection layer of wires and cables and corrosive gases must be prohibited in the storage warehouse of wires and cables.

5. If the storage time is long, the cable reel needs to be rolled appropriately. The rolling cycle is about three months, and the specific time can be set according to the situation. During the rolling process, the wires and cables should pay attention to rolling the edge of the reel stored downward to the top, so as to avoid the edge of a certain part of the reel being located at the bottom for a long time and getting damp and rotting.

6. Wires and cables are also products with a shelf life. Generally speaking, wires and cables should be used as much as possible within the shelf life. If the shelf life has expired, it should not exceed one and a half years, and the longest should not exceed the shelf life of two years. During the storage process of wires and cables, check whether the heads of wires and cables are intact.