English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

What Makes Modern Electric Wires More Reliable, Efficient, and Future-Ready?

2025-11-18

Electric wire plays a fundamental role in every residential, commercial, and industrial electrical system. Its performance directly impacts safety, energy transmission efficiency, device durability, and overall electrical stability. As power consumption continues to rise and new technologies demand cleaner and more reliable electricity, the expectations for electric wires have expanded far beyond basic conduction.

What Is Electric Wire and What Core Features Determine Its Performance?

Electric wire is a conductor used to transmit electrical energy from a power source to various endpoints. Its stability, conductivity, and insulation performance determine how safely and efficiently energy flows. Modern electric wires are designed to support high power loads, reduce heat generation, and maintain long-term durability in demanding environments.

What Defines the Basic Structure of an Electric Wire?

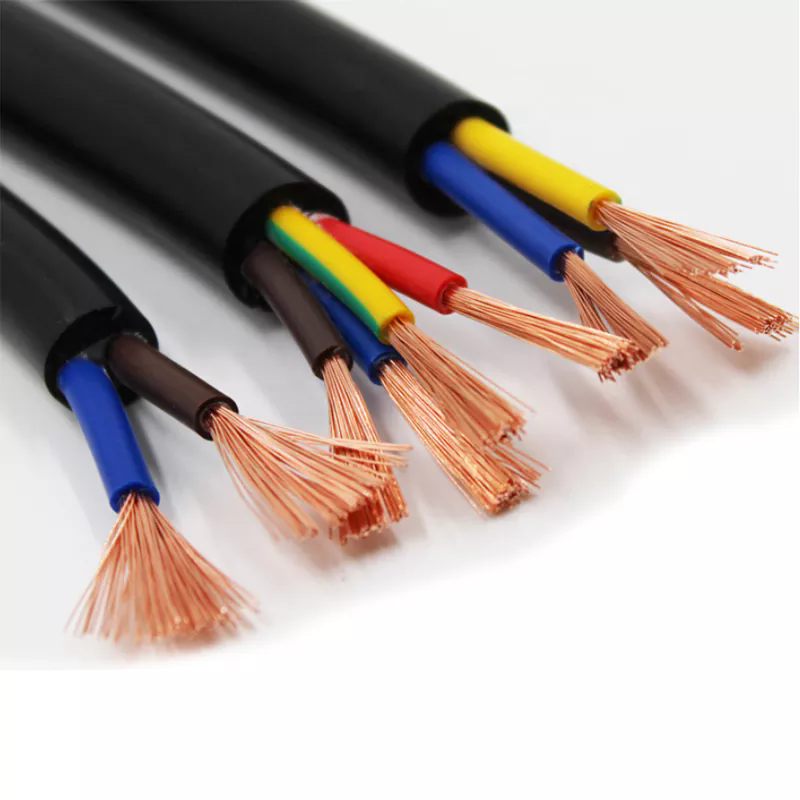

A typical electric wire consists of three major components:

-

Conductor: Usually copper or aluminum, responsible for carrying the electrical current.

-

Insulation Layer: Prevents current leakage, overheating, and short circuits.

-

Protective Sheath (Optional): Adds mechanical protection and environmental resistance.

What Materials Are Commonly Used and Why?

Copper:

Known for its outstanding conductivity, corrosion resistance, and flexibility. Ideal for residential, commercial, and industrial wiring.

Aluminum:

Lighter and more cost-efficient than copper. Suitable for large-scale power transmission where weight reduction is crucial.

PVC / XLPE Insulation:

-

PVC: Flexible, flame-retardant, and cost-effective.

-

XLPE: Highly heat resistant, ideal for high-load applications and long-term thermal stability.

What Technical Parameters Define Product Quality?

Below is a consolidated technical parameter overview used to assess electrical wire performance:

| Parameter | Description |

|---|---|

| Conductor Material | Pure Copper / Tinned Copper / Aluminum |

| Conductor Size Range | 0.5mm² – 240mm² |

| Insulation Material | PVC / XLPE |

| Rated Voltage | 300/500V, 450/750V, 0.6/1kV |

| Temperature Rating | -20°C to 90°C (PVC), up to 105°C (XLPE) |

| Flame Retardancy | Optional FR, LFH, or low-smoke halogen-free |

| Color Options | Red, Yellow, Blue, Green, Black, White |

These parameters ensure the product meets strict application requirements across residential, industrial, and commercial environments.

1.4 What Applications Require Professional-Grade Electric Wire?

-

Household power distribution

-

Industrial machinery wiring

-

Lighting systems

-

Electrical appliances

-

Automotive and marine wiring

-

Power control cabinets

-

Solar and renewable energy systems

Each application requires careful selection based on voltage, temperature, flexibility, and environmental exposure demands.

Why Are High-Quality Electric Wires Critical for Safety, Efficiency, and Long-Term Value?

Why Does Conductor Quality Strongly Influence Performance?

The conductor is the heart of the electric wire. Its material, purity, and size determine:

-

How efficiently the current flows

-

How much heat builds up during operation

-

How long the wire can operate without degradation

High-purity copper reduces resistance, ensures stable energy transmission, prevents overheating, and significantly extends service life.

Why Is Proper Insulation Essential for Safe Usage?

Insulation acts as the protective barrier between electricity and the surrounding environment. High-quality insulation materials:

-

Prevent electrical leakage

-

Reduce fire risks

-

Provide resistance to chemicals, oil, and moisture

-

Maintain performance under thermal stress

Choosing low-quality insulation can lead to dangerous failures such as short circuits, fires, and equipment damage.

Why Does Cable Size Matter for Real-World Applications?

Incorrect cable sizing causes:

-

Voltage drop

-

Excessive heat buildup

-

Reduced performance of electrical devices

-

Safety hazards

Larger conductor sizes are used for higher current loads, while smaller sizes suit low-power devices. Proper sizing extends lifespan and boosts energy efficiency.

Why Are Industry Certifications Important?

Certifications reflect compliance with international safety and performance standards. They assure consumers that the product has undergone:

-

Electrical endurance tests

-

Heat resistance evaluation

-

Insulation quality verification

-

Flame-retardant capability checks

Recognized certifications strengthen trust and help products enter global markets.

How Do Electric Wires Deliver Enhanced Performance and Meet Diverse Application Needs?

How Do Different Insulation Types Improve Functionality?

PVC Insulation:

-

Ideal for indoor applications

-

Cost-effective

-

Easy to install

-

Provides adequate flame resistance

XLPE Insulation:

-

Designed for high-temperature stability

-

Suitable for heavy-duty machinery

-

Offers longer service life and less aging

-

Improves energy transmission efficiency

How Are Electric Wires Manufactured to Ensure Reliability?

The production process includes:

-

Conductor drawing: Metal is drawn into precise wire diameter.

-

Annealing: Enhances conductivity and flexibility.

-

Insulation extrusion: Insulation is uniformly applied with strict thickness control.

-

Quality testing: Electrical, mechanical, and aging tests ensure stability and compliance.

-

Final packaging: Protects during transport and storage.

Each step affects the final performance of the wire.

How Does Flame-Retardant Technology Improve Safety?

Flame-retardant insulation helps:

-

Prevent fire spread

-

Reduce toxic gas emission

-

Offer higher resistance to heat deformation

-

Protect users and equipment during overload conditions

Low-smoke halogen-free materials are increasingly preferred due to safety and environmental benefits.

How to Choose the Right Electric Wire for Different Industries?

Home Wiring:

Opt for copper conductors with PVC insulation, stable performance, and standard voltage ratings.

Industrial Facilities:

Use XLPE-insulated wires that support high load and heat resistance, suitable for machinery and production lines.

Automotive Wiring:

Requires flexible and heat-resistant wires with durable insulation for engine bay environments.

Solar Systems:

UV-resistant, heat-stable, and flame-retardant wires provide long-term outdoor durability.

Future Trends: How Will Electric Wire Technology Continue to Evolve?

Trend 1: Higher Heat Resistance and Extended Lifespan

Modern devices demand higher operational temperatures. The market is shifting towards advanced XLPE and halogen-free insulations that maintain performance in demanding environments.

Trend 2: Smarter, More Energy-Efficient Wiring

As energy-saving systems gain popularity, wiring is evolving to:

-

Reduce voltage drops

-

Improve conductivity

-

Optimize transmission efficiency

-

Support smart home systems and IoT devices

Electric wires need to integrate better with intelligent electrical management.

Trend 3: Eco-Friendly Materials and Sustainability

Industries increasingly adopt recyclable insulation materials and low-smoke halogen-free formulations to reduce environmental impact. Sustainable production is becoming a major purchasing standard.

Trend 4: Customization for Specialized Industry Use

Fields like automotive, aerospace, and renewable energy require tailor-made wire structures, including:

-

Multi-layer shielding

-

Extreme heat resistance

-

Lightweight aluminum alloys

-

Extra-flexible designs

Customization will reshape electric wire manufacturing to meet industry-specific performance demands.

Common FAQs About Electric Wire

Q1: What wire size should be used for household circuits?

A1: Wire size selection depends on the total current load of the circuit. Standard household lighting often uses 1.5mm² copper wire, while outlets and high-power appliances may require 2.5mm² or higher. Correct sizing prevents overheating and ensures long-term safety.

Q2: Why are copper wires preferred over aluminum wires?

A2: Copper has higher conductivity, lower resistance, and better flexibility compared to aluminum. It transmits electricity more efficiently, reduces heat buildup, and offers longer lifespan, making it the preferred choice for most residential and commercial wiring systems.

Q3: How to determine whether PVC or XLPE insulation is needed?

A3: PVC is suitable for standard indoor wiring where temperature exposure is moderate. XLPE should be used in environments requiring high heat resistance, outdoor durability, or heavy load support. Selection depends on operating temperature, voltage, and application demands.

Conclusion: How Are High-Quality Electric Wires Shaping the Future of Electrical Systems?

Electric wires are critical to the reliability, safety, and long-term stability of electrical systems. The advancement of conductor materials, insulation technologies, flame-retardant capabilities, and smart energy transmission is transforming the electrical industry. As demand for efficient and sustainable power grows, high-grade wiring solutions become indispensable across residential, commercial, and industrial sectors.

Premium electric wires deliver enhanced conductivity, energy efficiency, thermal protection, and long-term durability. These advantages ensure safer installations, reduced maintenance, and compatibility with evolving electrical technologies. As the market continues to prioritize safety, efficiency, and sustainability, professional-grade products from trusted manufacturers will continue to shape the future of wiring infrastructure.

For high-performance and durable wiring systems, DAYA provides dependable solutions designed to meet various industry requirements.

For product details or customized specifications, contact us for professional support.