English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

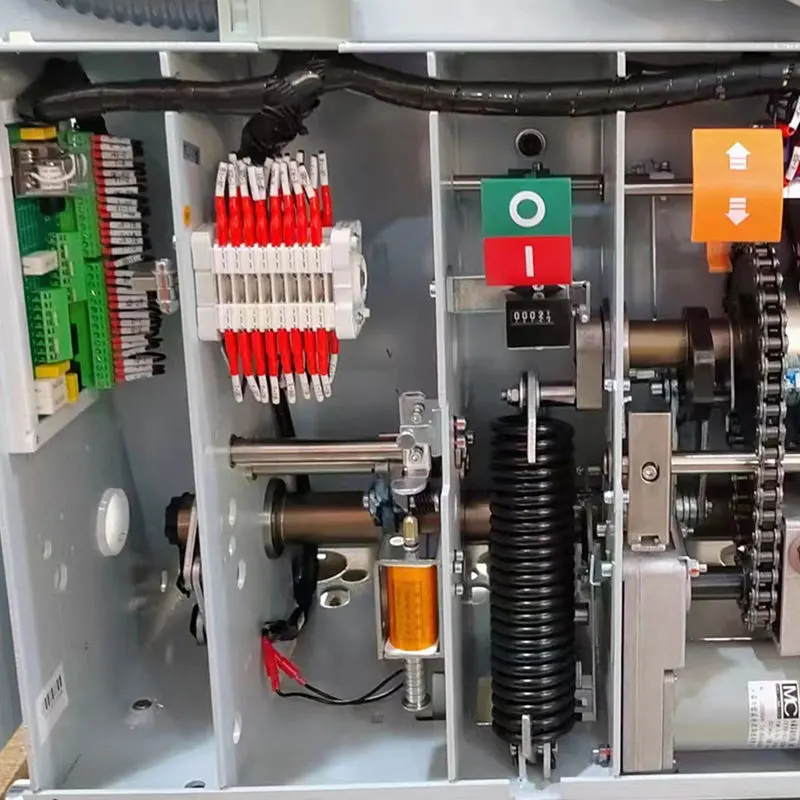

How To Perform Routine Maintenance On Vacuum Circuit Breakers?

2025-03-12

In order to keep the vacuum circuit breaker in good working condition, regular maintenance management must be done.

1. Keep the gas path clean: humid or unclean air and unclean pipelines may cause adverse consequences

(1) Humid gas decomposes into mixed gases such as hydrogen and oxygen under the action of the arc, destroying the insulation between the breaks after the main contacts are disconnected, making it difficult to ignite the arc or the arc reignites. In severe cases, it may cause the arc extinguishing chamber to burst.

(2) The insulation strength of the supporting porcelain bottle and the inner cavity of the arc extinguishing chamber is reduced, causing surface discharge.

(3) Foreign matter such as paint and rust in the pipeline may block the gas port, causing the main circuit breaker to malfunction and jam. In addition, if foreign matter enters the arc extinguishing chamber, it may cause poor contact of the main contact, causing the nonlinear resistor to burn due to long-term power-on, and in severe cases, it may cause the nonlinear resistor porcelain bottle to burst.

2. Regularly replace rubber parts

The main circuit breaker is a pneumatic electrical device with a complex structure. Each component has high requirements for sealing performance. To ensure good sealing performance, rubber parts should be replaced regularly.

3. Regularly check the main components

The arc extinguishing chamber, nonlinear resistor, main valve, transmission air cylinder and other main components should be checked regularly to maintain good technical status.