English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

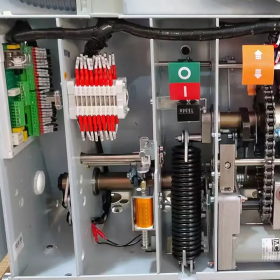

Why are vacuum circuit breakers so popular?

2025-09-16

Vacuum circuit breakers have gradually replaced traditional oil circuit breakers and air circuit breakers, becoming the mainstream choice in the field of power system protection and control. So why are vacuum circuit breakers so popular?

Strong arc extinguishing ability and opening performance:

Vacuum circuit breakers utilize a high vacuum as the arc extinguishing and insulation medium. When the contacts separate and an arc is generated, in a vacuum environment, there are no ionizable gas molecules, allowing the arc to be extinguished extremely quickly and completely at the zero point of the current. Moreover, vacuum circuit breakers can reliably cut off short-circuit currents of up to several tens of kiloamperes, with more reliable response. They can also significantly reduce contact erosion and improve electrical lifespan. At the same time, the full opening speed of vacuum circuit breakers is fast, with the full opening time typically less than 40ms, which is conducive to system stability and reduces the risk of equipment downtime due to maintenance.

Long electrical lifespan and low maintenance requirements:

Since there are almost no harmful substances produced during the vacuum arc extinguishing process, the contact wear is extremely low. This makes its electrical lifespan far exceed that of traditional oil circuit breakers, with more full-capacity opening capacity times. The key point is that the vacuum arc extinguishing chamber of the core component adopts a fully sealed structure, and its internal state is not affected by external environmental conditions, so it can be maintained without maintenance during operation, which greatly reduces the operation and maintenance costs and the risk of equipment downtime due to maintenance.

High safety and environmental protection:

There is no flammable or explosive insulating oil or compressed gas inside the vacuum circuit breaker, eliminating the potential explosion and fire risks similar to oil circuit breakers, making it the optimal choice for high-risk locations such as coal mines, oil fields, and chemical plants. At the same time, the vacuum circuit breaker eliminates the harmful sulfur hexafluoride gas that affects the greenhouse effect. Its core vacuum medium is pollution-free, non-toxic, and has a simple and environmentally friendly process for waste disposal. Moreover, when cutting small inductive currents, its clamping value is relatively low, resulting in a smaller operating overvoltage, further enhancing the operational safety of the system.

Compact structure and strong adaptability:

The core application of vacuum technology significantly optimizes the overall design of the circuit breaker, making it exhibit excellent compactness and environmental adaptability. The volume and weight of the vacuum arc extinguishing chamber are much smaller than those of oil chambers or gas chambers required for the same voltage level, which directly leads to the refinement of the overall structure of the circuit breaker, saving a lot of valuable space for switch cabinets. At the same time, the operation energy required for opening and closing is low, allowing it to be matched with small-sized and highly reliable spring operating mechanisms. More importantly, due to the excellent sealing performance of the vacuum arc extinguishing chamber, the internal state of the circuit breaker can effectively isolate external environmental interference, even in complex and harsh conditions such as humid heat, pollution, and high altitudes where traditional switch equipment cannot operate stably, it can maintain excellent performance.

| Advantage | Key Features | Comparison/Benefit |

| Strong Arc Extinguishing | Uses high vacuum medium. Extinguishes arc instantly at current zero. | Interrupts high short-circuit currents (tens of kA). Fast opening time (<40ms). Reduces contact erosion. |

| Long Electrical Life | Minimal contact wear. Fully sealed vacuum interrupter. | Far exceeds oil breaker lifespan. More full-capacity operations. Truly maintenance-free. Lowers operating costs and downtime risk. |

| High Safety & Eco-Friendly | No flammable oil/gas. No SF6 greenhouse gas. Low operation overvoltage. | Eliminates explosion/fire risks. Ideal for hazardous locations. Pollution-free medium. Simple eco-friendly disposal. Safer for systems. |

| Compact & Adaptable | Small lightweight interrupter. Low operating energy. Excellent sealing. | Saves significant switchgear space. Enables compact designs/retrofits. Uses smaller reliable spring mechanisms. Performs reliably in harsh environments (humidity, pollution, altitude). |